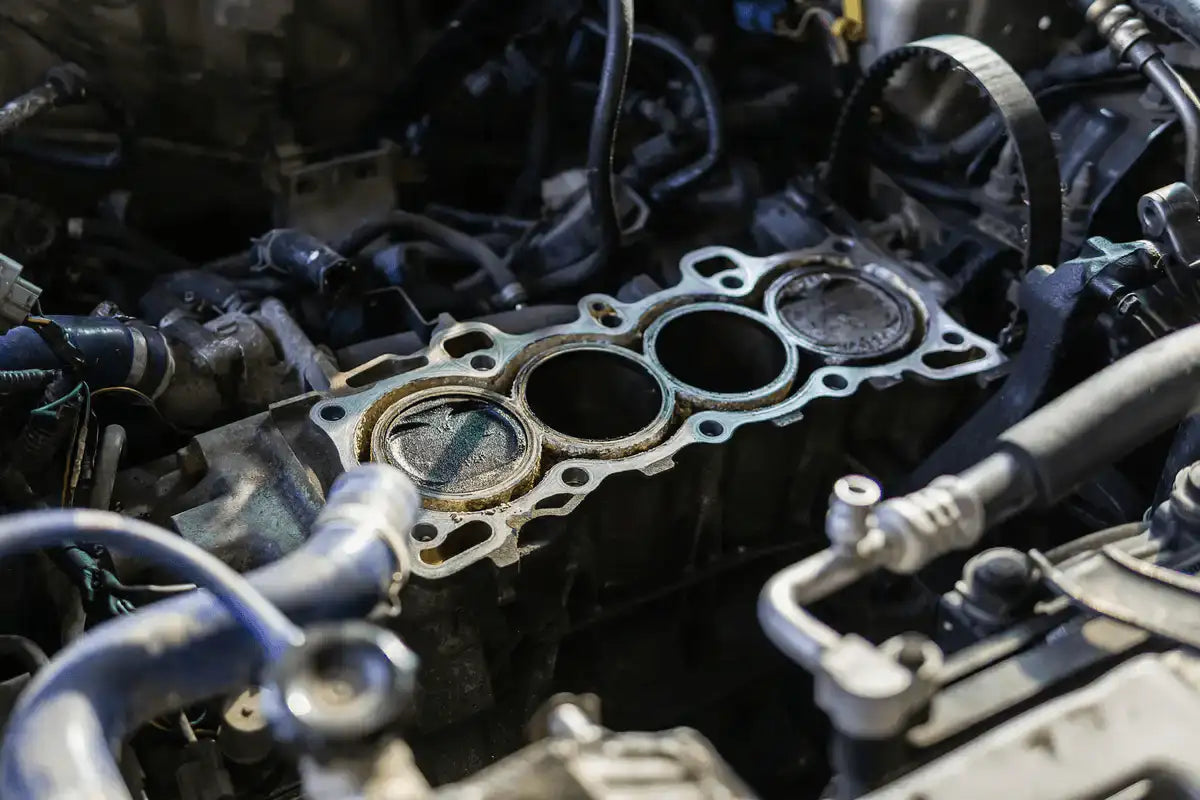

The engine is the heart of every vehicle, making its upkeep essential for optimal performance. But how can we achieve this? There are numerous approaches: from practicing good driving habits to conducting regular fluid changes, and more. Recently, engine flushing has emerged as a popular maintenance technique. This process involves cleaning the engine of accumulated contaminants, primarily carbon and soot, using specialized chemical solutions known as engine flushes. These flushes dissolve the deposits, which are then drained away with the engine oil. Although widely favored, these substances still provoke safety concerns among some users, particularly regarding their effects on the engine’s rubber seals. What does this mean in practice? Can using an engine flush potentially damage the system’s components?

Is engine flushing safe?

Engine flushing is designed to eliminate built-up contaminants from the system, aiming to enhance rather than harm the engine. However, the safety and effectiveness of flushing largely depend on how the procedure is conducted. For a risk-free flush, it is critical to use a high-quality engine flush product. Opting for inappropriate substitutes, like diesel oil, can pose risks. Surprisingly, some vehicle owners have used such alternatives for cleaning. We strongly advise against this approach! Using diesel oil for flushing can lead to severe issues such as crankshaft failure due to loss of bearing pressure, which occurs due to harmful vapors reacting with the diesel. Additionally, even if a crankshaft failure does not occur, flushing with fuel can dislodge large chunks of hardened contaminants, quickly leading to the clogging of the engine oil filter.

Why is there skepticism about using engine flushes?

Online there are views suggesting that regular engine oil changes are sufficient for removing contaminants from the system. However, in reality, while lubricants do a good job of cleaning out general dirt, they lack the strength to fully deal with severe cases such as heavily baked-on carbon deposits. This is where engine flushes come into play, as these are chemical products made from potent solvent mixtures designed to dissolve tough residues. It's precisely because of their chemical composition that some people fear they might damage critical engine components, particularly rubber elements, potentially leading to leaks.

Engine flushes and rubber components: can the products cause leaks? It depends

Let's delve into whether engine flushes used during oil changes are safe for rubber seals. It's difficult to give a definitive answer to this question because it largely depends on the specific product chosen and how it's used. Focusing on the first aspect, the market offers chemical flushes that contain various acids and esters. These components are not conducive to the long-term health of the engine – be aware that such chemical compounds can absorb moisture from seals, leading to a reduction in their volume, which can result in leaks. Another risk factor is the improper application of these products. Not following the manufacturer's instructions could lead to the flush adversely affecting the engine's interior, particularly the rubber seals. For instance, adding twice the recommended amount of flush and leaving it overnight could cause seal failure when the old oil and flush are drained. This is why it's crucial to read and follow the specific usage instructions for each product – adhering to these guidelines ensures that the flush will not contribute to any leakages.

Choosing the right engine flush for removing carbon build-up

An engine flush does not inherently damage the engine if it is a high-quality product. Selecting a flush free from the previously mentioned esters and acids ensures the safety of the engine. It's important to note that flushes should do more than just clean the system of carbon, soot, and other deposits. They should also protect the engine during the flushing process, which involves a reduction in oil viscosity that could otherwise leave engine components less protected during operation. Thus, using the right flush not only maintains cleanliness but also enhances the overall safety and functioning of the engine.

A great example of a chemical flush is the TEC 2000 Engine Flush – a product that is completely acid-free, making it safe for both rubber and silicone engine seals. This flush is renowned for its effectiveness, reaching the furthest recesses of the engine system to thoroughly remove all contaminants from piston ring grooves, valve lifters, and oil passages. With its neutral pH, it does not acidify the oil environment, ensuring that the engine oil maintains its optimal alkalinity, thus protecting the engine from potential corrosion.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.